Chinese team creates ‘highly efficient, flexible’ silicon solar cells

- Breakthrough technology has broad applications in aerospace, wearable electronics and portable power sources, according to scientists

- They say innovative structure allows cells to be folded like a sheet of paper, and study suggests mass production is viable

Chinese scientists who have turned hard silicon solar cells into an elastic form as thin and soft as paper say their breakthrough technology has broad applications in aerospace, wearable electronics and portable power sources.

Over the past few years, advances in materials and manufacturing have led to impressive gains in the efficiency of silicon solar cells. They now boast a light-electricity conversion rate of 26.8 per cent – approaching the theoretical limit of 29.4 per cent.

Silicon solar cells represent about 95 per cent of the solar cells used in the photovoltaic market. They have been widely used in ground-based solar farms and distributed photovoltaics since manufacturing and power generation costs came down.

But developing commercially viable and highly efficient solar cells that are lightweight, flexible and low cost – and that can be used on a large scale – is a challenge.

Thin-film solar cells currently in use are made from amorphous silicon, cadmium telluride, organics and perovskites.

They do “exhibit flexibility”, according to Liu Wenzhu, a professor at the new energy technology centre of the Chinese Academy of Sciences’ Shanghai Institute of Microsystem and Information Technology (SIMIT).

“But their use is limited because of their low power conversion efficiency … the release of toxic materials into the environment, inferior performance in the case of large areas and unstable operating conditions,” Liu said.

His team has come up with an innovative structure for silicon solar cells to make them flexible – and they say the study suggests mass production is also viable.

The scientists – from SIMIT, the Changsha University of Science and Technology and the Saudi Arabian Oil Company – published their study findings in the peer-reviewed journal Nature on May 24.

The development could open up new opportunities in sectors like wearable electronics, mobile communications, mobile energy for vehicles, integrated photovoltaics in architecture, and in aerospace.

As new entrants eye China solar sector, overcapacity and price war concerns mount

The team began by observing silicon solar cells placed under bending stress using high-speed cameras. They found that cracking always began at a sharp V-shaped groove at the edge of the silicon wafer – an area they defined as its “weak point”.

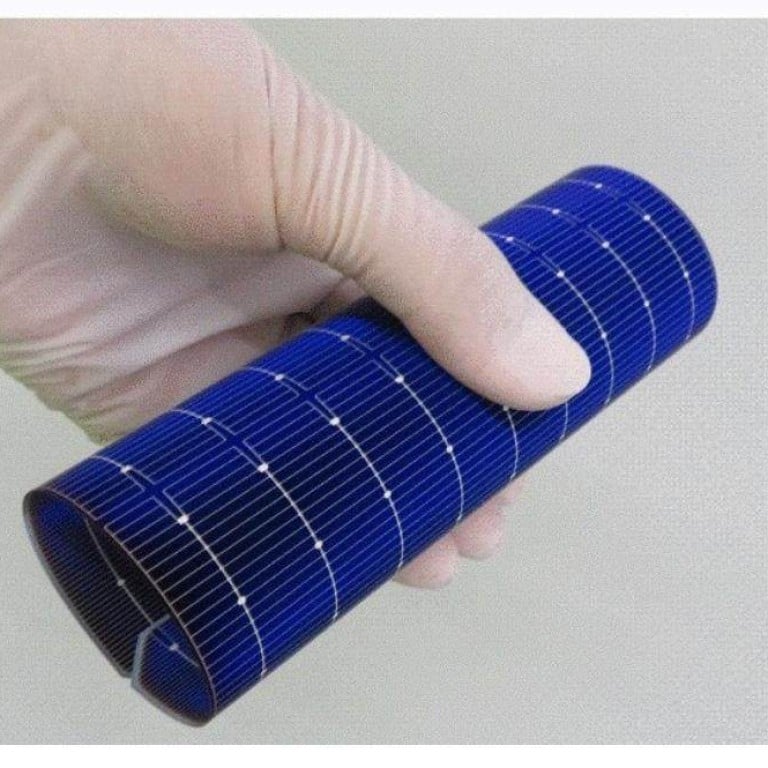

“Understanding the fracturing behaviour of solar cells led us to alter the structure of the silicon wafer’s edge area. We replaced the sharp ‘V’ grooves with smoother ‘U’ grooves, which effectively distribute the bending strain and suppress the fracturing behaviour,” Di Zengfeng, corresponding author of the study, said in a report on SIMIT’s website on Wednesday. “The final result is a highly efficient, lightweight and flexible silicon solar cell.”

That strategy was only used at the edge of the wafer, so it does not have an impact on the power conversion efficiency of the solar cell, Liu Zhengxin, another corresponding author, said in the report.

“However, it does significantly increase the solar cell’s flexibility, which offers broad application prospects,” he said.

The silicon solar cell has unprecedented flexibility, according to the paper. Measuring 60 micrometres, it can be folded like a sheet of paper. It can also withstand repeated bending, with a bend radius of less than 5 millimetres and bend angles exceeding 360 degrees.

The researchers also conducted durability testing under different conditions. The cells retained 100 per cent of their power conversion efficiency after 1,000 side-to-side bending cycles. They also retained 99.62 per cent of their power after thermal cycling between minus 70 degrees Celsius (minus 94 Fahrenheit) and 85 degrees Celsius (185 Fahrenheit) for 120 hours.

Has a Chinese-Swiss team cracked the code for making solar energy cheaper?

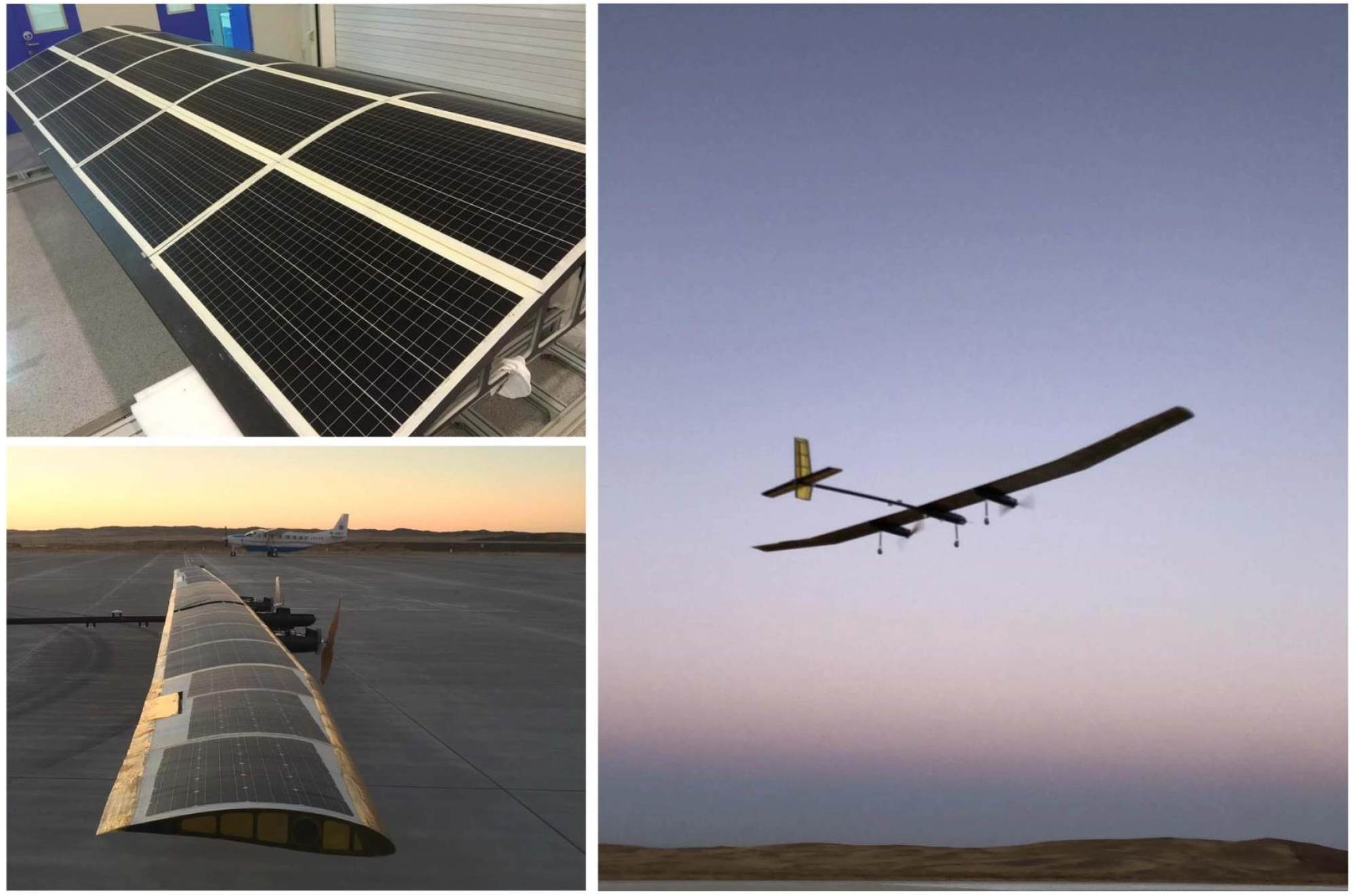

In a wind resistance test, researchers attached a cell module to an inflated gasbag and used a powerful fan to model the effect of wind blowing at a speed of 30 metres per second during a violent storm. After continuous air impact for 20 minutes, the relative power loss was only 3.07 per cent, suggesting its potential use in aerospace, such as spy balloons.

According to the report, the research team’s large-area flexible photovoltaic modules have already been successfully used in near-space vehicles, integrated building photovoltaics, and vehicle-mounted photovoltaics.

But the team remain cautious about the manufacturing technology. “More in situ tests need to be performed before large-scale production to guarantee consistent stability under real-life operating conditions where stressors may occur simultaneously,” Liu Wenzhu said in the paper.