Learning from polar bears, China’s aerogel fibre weaves a way for ultra-thin winter clothing

- Aerogel, the world’s lightest solid is usually very brittle, but scientists have overcome its fragility in a breakthrough

- By looking at the structure of polar bear hair, researchers have created an aerogel fibre which can be woven into clothing

The development of the biomimetic fibres, notable for their performance and durability, could have various applications.

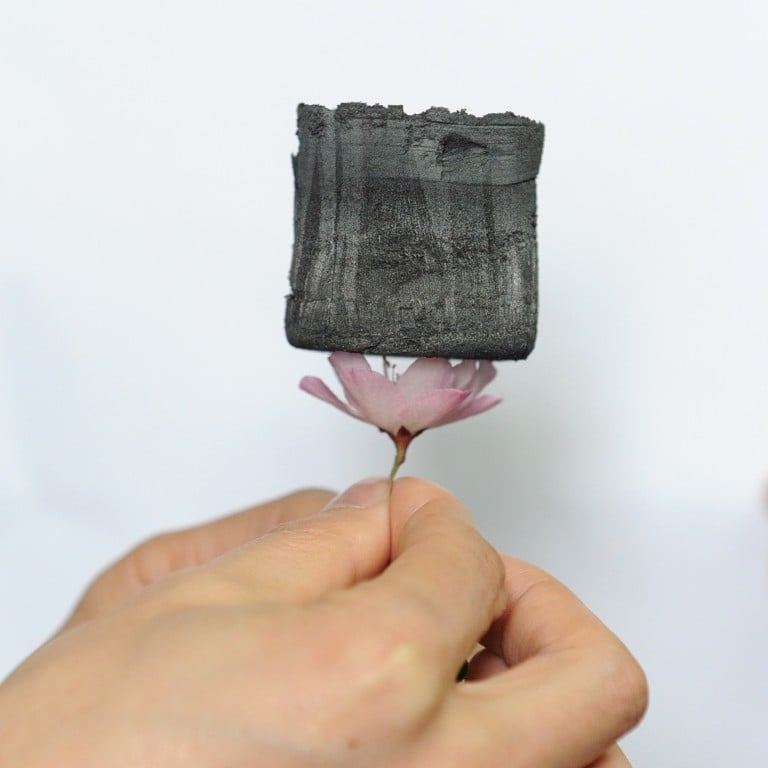

Aerogel, the world’s lightest solid material, has long been valued for its thermal insulation properties.

Traditional aerogel, made by replacing the liquid in a gel with air, is extraordinarily light, resembling a solid cloud of smoke. Its high porosity gives it exceptional heat resistance, but this also makes it brittle and challenging to process, limiting its use in civilian applications.

Led by associate professor Gao Weiwei and professor Bai Hao, the team published its findings in the peer-reviewed journal Science.

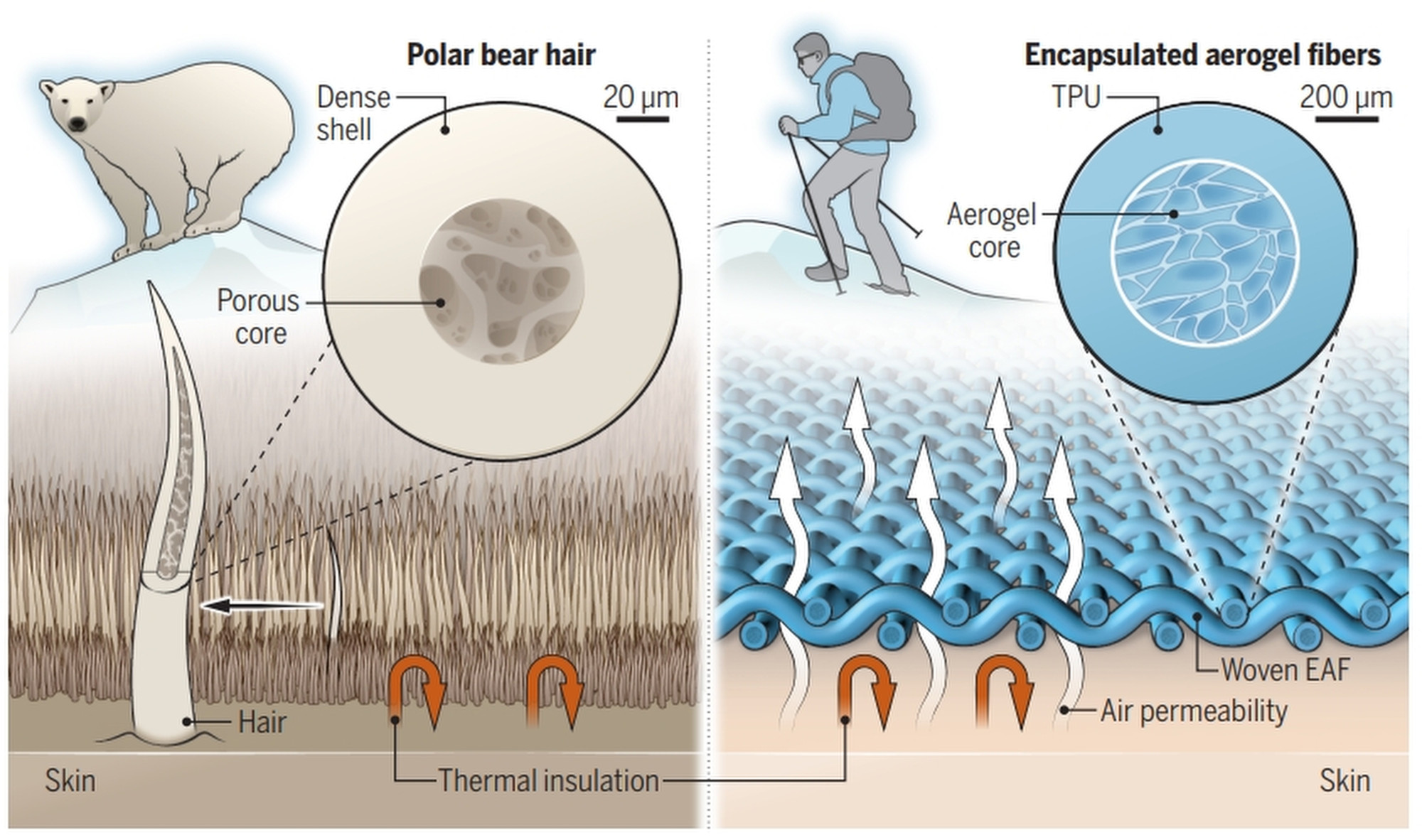

“We designed an encapsulated aerogel fibre (EAF) with similar thermal insulation mechanisms and developed a facile two-step fabrication route to mimic the core-shell structure,” Bai outlined in the paper.

The team developed a strong polymeric aerogel fibre with lamellar pores and cased it within a thin, stretchable rubber layer. This approach retained the thermal insulation properties of traditional aerogel while improving its suitability for mechanical applications like knitting or weaving.

Unlike conventional silica aerogel, which is brittle,, the EAF can be bent and twisted.

“Despite its high internal porosity of over 90 per cent, our fibre is stretchable up to 1,000 per cent strain, significantly outperforming traditional aerogel fibres, which stands at about 2 per cent strain,” Bai said.

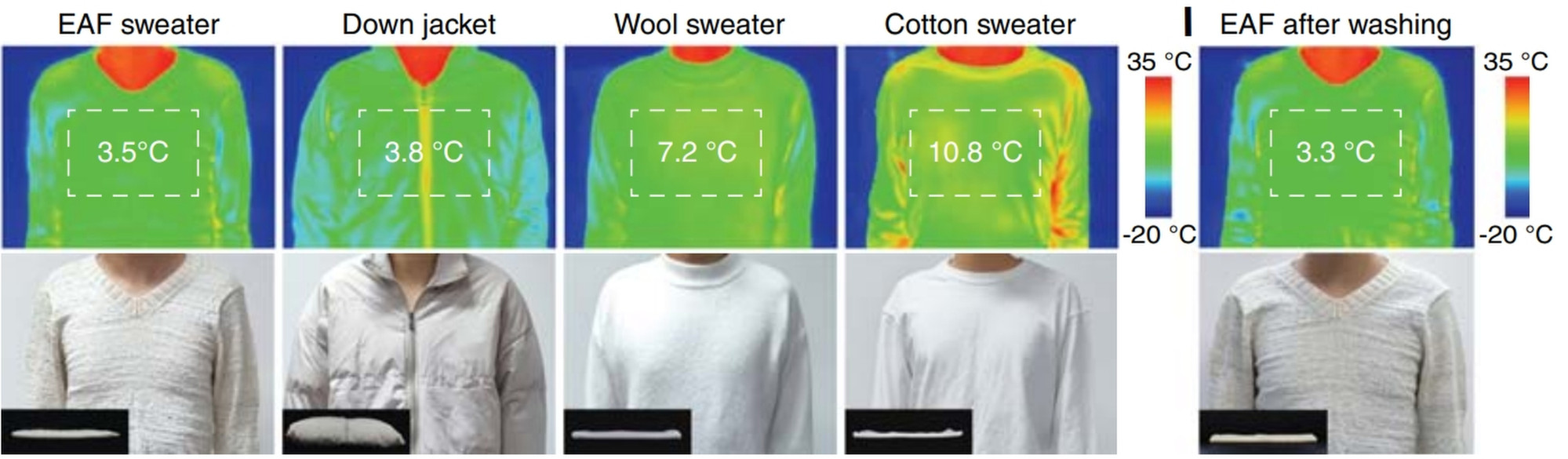

They showed the practicality of EAF by weaving a jumper and comparing its thermal insulation to common textile materials. The thermal insulation of the EAF jumper was comparable to that a traditional down jacket but only one-fifth as thick.

In an experiment, a volunteer wore textiles made of EAF, down, wool, and cotton in a -20 degree Celsius environment. The surface temperatures of these materials were 3.5 degrees, 3.8 degrees, 7.2 degrees, and 10.8 degrees respectively, indicating the superior insulation of EAF.

As well as being strong and stretchable, EAF can also be washed and dyed, improving its use in practical applications.

Traditional silica aerogel will absorb water and collapse on itself. As a result, it quickly loses its thermal insulation qualities in wet or humid environments. However, EAF maintains its performance even after machine washing.

“The fibre also retains its properties after 10,000 stretching cycles, indicating its potential for multifunctional use beyond thermal insulation textiles,” Bai said.

Professor Zhang Xuetong of the Suzhou Institute of Nano-tech and Nano-bionics at the Chinese Academy of Sciences, highlighted the potential of the aerogel fibres in advanced thermal textiles. However, he noted the gap between existing technology and capacity for mass production.

“Challenges exist regarding how to develop fast spinning technology and resolve the continuous fabrication that is necessary for mass production,” he said.

As well as its potential for civilian use, EAF fibre also holds promise for industries that are already familiar with aerogels.

“EAF textiles feature excellent thermal insulation and multifunction and have great potential in areas such as military uniforms and spacesuits in extremely cold environments,” Bai noted in the paper.